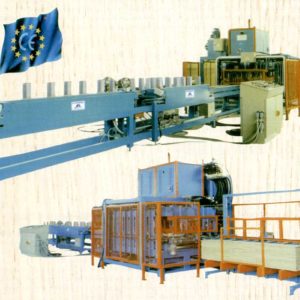

AUTOMATIC PRESSING LINES FOR STRIP PANEL PRODUCTION

EILT Mod. 2200 – 2500 – 3000 – 3500 HF or OD

The standard equipment of these plants includes a preparation surface for the panels to be glued, with automatic feeding system of the glue spreading unit, a glue spreading unit controlled by motorised rolls or pneumatic pump, with working speeds between 30 and 120 m/min, a panel composition surface equipped with a press-introduction carriage, and a pneumatic press with working pressures reaching 18 kg/cm2 on the horizontal axis.

PDF DOWNLOAD

The standard dimensions of these plants, referring to the press bed, are the following:

mm. 2200 x mm. 1300 Mod. EILT 2200

mm. 2500 x mm. 1300 Mod. EILT 2500

mm. 3000 x mm. 1300 Mod. EILT 3000

mm. 3500 x mm. 1300 Mod. EILT 3500

and other dimensions are available on request.

The 1300 mm depth is not binding since the vertical pressure is impressed from the top, thus allowing the plant to work in continuous cycle, the minimum working pressure is 10 mm and the maximum working pressure is 80 mm. The glue polymerisation system can be of the hot plate type, through water or diathermic oil heating systems, or of the high frequency type, through generators of our production; the working cycle can be automatic or manual; in both cases, it is controlled by a PLC, and an operator interface allows to enter the data necessary to the cycle setting.

The lines can also be equipped with special multi-track loaders, straight or bent cut rear cutters, unloaders-stackers and automation systems for feeding and unloading with other machines.

Contact us

Fill out the form below.

Ask any question or request a free quote

Call

+39 335 64 44 610

Contacts

Fill in and send this form.

Fields marked with an asterisk "*" are required for future contact.

Address

Via A. Modigliani 19b

10036 Settimo Torinese (TO)